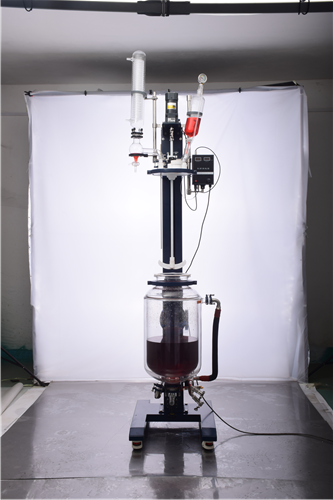

The three-layers glass reactor has the same functions as the single layer and the double layer. It is a material synthesis instrument in the fields of chemical, petroleum, chemical, bio-pharmaceutical, etc. It can be distilled, concentrated, refluxed under constant temperature and constant temperature. Separation, purification and other reactions. The three-layers glass reactor is updated on the basis of the double-layers glass reactor. From the appearance, the three-layers glass reactor is not much different from the double-layers glass reactor. The main difference is that the kettle body has one more layer. glass.

The working principle of the three-layers glass reactor

The three-layers glass reactor is composed of three layers of glass and two sets of interlayers, which can provide a stirring function and control evaporation and reflux of the reaction solution. The interlayer of the inner layer of the three-layers glass reactor is used for heating or cooling, and the jacket interlayer is used for vacuuming, and the temperature of cooling or heating of the materials in the kettle can be kept as much as possible under the vacuum of the outer interlayer. The material is reacted in the reaction vessel, and the completed material is discharged from the PTFE discharge port at the bottom of the kettle.Product features of the three-layers glass reactor

1. This product is more ideal and practical. The triple elastic design of the support frame ensures the heavy-duty reaction operation and is compatible with the upgrade of the lift.2, using high borosilicate glass material (GG17), with high quality physicochemical properties.

3, can be used in high temperature range from high temperature 200 ° C to low temperature -80 ° C.

4. The surface of the bracket is sprayed with Teflon, which is corrosion-resistant and keeps the whole machine beautiful and life-use.

5, advanced frequency control, frequency converter controller, internal components with vacuum coating protection, corrosion resistance, optional full explosion-proof, safe and reliable.

6. Three-layer kettle body, * layer is vacuum insulation layer body for heat preservation, and second interlayer layer provides reflection for providing heat and cold. The fully transparent reaction bottle makes the process of reflection clear at a glance.

7, polytetrafluoroethylene (PTFE) components sealed, special design, can maintain the market similar products zui good vacuum (-0.098mpa or so), the discharge valve can release concentrated liquid and trace solids, domestic ling first.

8. Jacket pressure control device is the company's new technology for the protection of the kettle body, making the work safer and more reliable.

9. The cavity and jacket are designed to have no dead angle, anti-corrosion and pollution-free structure.

10. After the heat transfer medium is over, it can be completely eliminated without any accumulation of liquid.